United Testing Emerging Renewables

For Members As Markets Change

by

KANYON PAYNE

It seems like ancient history now, but United in 2012 was a proponent of renewable energy even as wind and solar installations began cropping up throughout its service territory. Today, the numbers of them have swelled to a total of 322 solar and 40 wind applications that have been interconnected within its distribution system.

At the cusp of those residential system installations, United wanted to know more. The cooperative wanted to develop a practical knowledge base and a fundamental understanding of those developing technologies by internally investigating installation costs, energy production and maintenance requirements associated with renewable energy applications.

To do so, United initially set out to install small scale wind and solar resources at each of its six offices. However, the cooperative settled on the installation of nine solar arrays and four wind turbines that were designed as renewable energy learning labs.

The goal was to gather and compare research data on a variety of renewable systems, to provide members the opportunity to see those resources up-close and to share ongoing research findings with the membership. United used a variety of installers, equipment, and types of systems to determine the differences between each type of system and to sort out their pitfalls and their merits. During the seven years of their operation, United has observed many nuances and obtained its own internal analysis of these resources.

United Office Learning Labs Fleet

- Stephenville: a 1.8 kW, and a 1.7 kW solar array.

- Burleson: a 2.3 kW solar array, and a 10 kW wind turbine.

- Cleburne: 3 solar simulation systems of similar size but different mounting systems including a 1.38 kW pole mounted system, a 1.38 kW tracking system, and a 1.48 kW roof mount system; a 2.5 kW wind turbine, and a 3.5 kW wind turbine.

- Granbury: a 2.4 kW wind turbine, and a 1.1 kW solar array.

- Meridian: 1.44 kW tracking solar array.

- Possum Kingdom Lake: a 1.26 kW solar array.

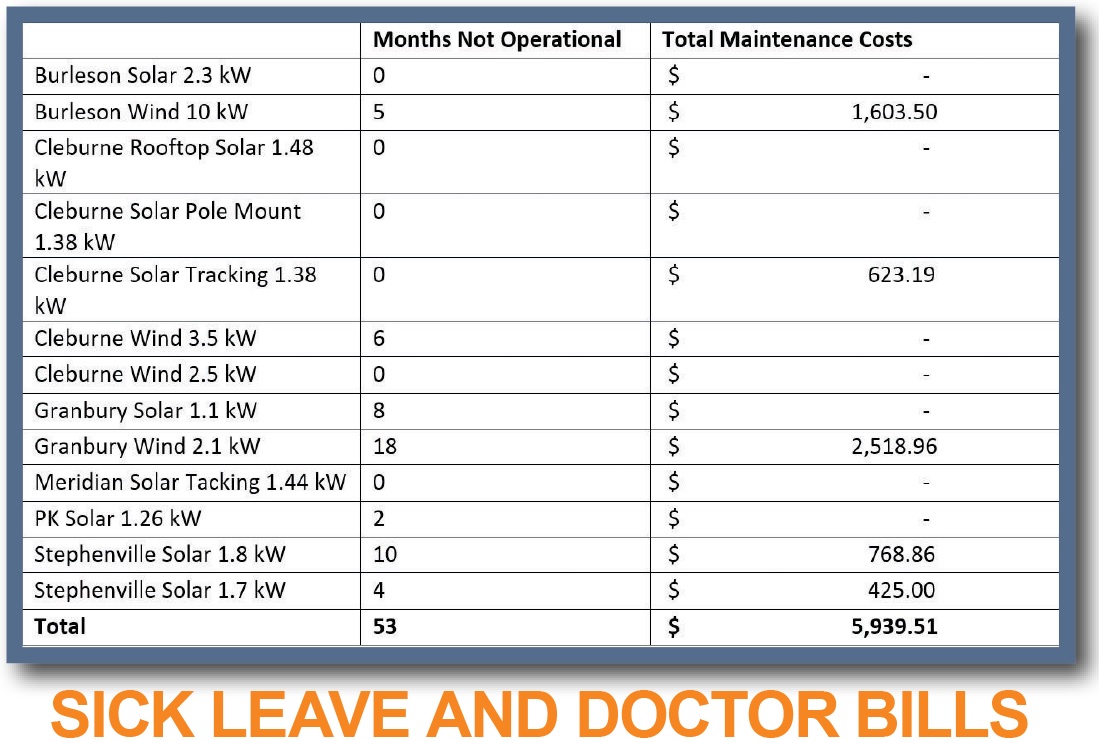

One of the more practical observations United can share is the caveat that consumers cannot expect installation costs for such resources to be the final costs. More than half of the United systems installations have had a mechanical failure or maintenance issue that caused them to become inoperative for a significant period. Obviously, this is important for several reasons: 1) nothing is being recovered on a significant investment while the resource is idled, 2) the resources aren’t always easy to repair 3) the repairs aren’t inexpensive.

In United’s experience, some of these systems have been out of production for 2- to 18-month periods. The time the systems were offline was due to ordering parts or locating a qualified contractor to perform needed repairs. As an example, above is a maintenance and repair log for each United system, showing how many months it may not have been in operation due to a mechanical failure, and the total cost for the repair or maintenance of the system.

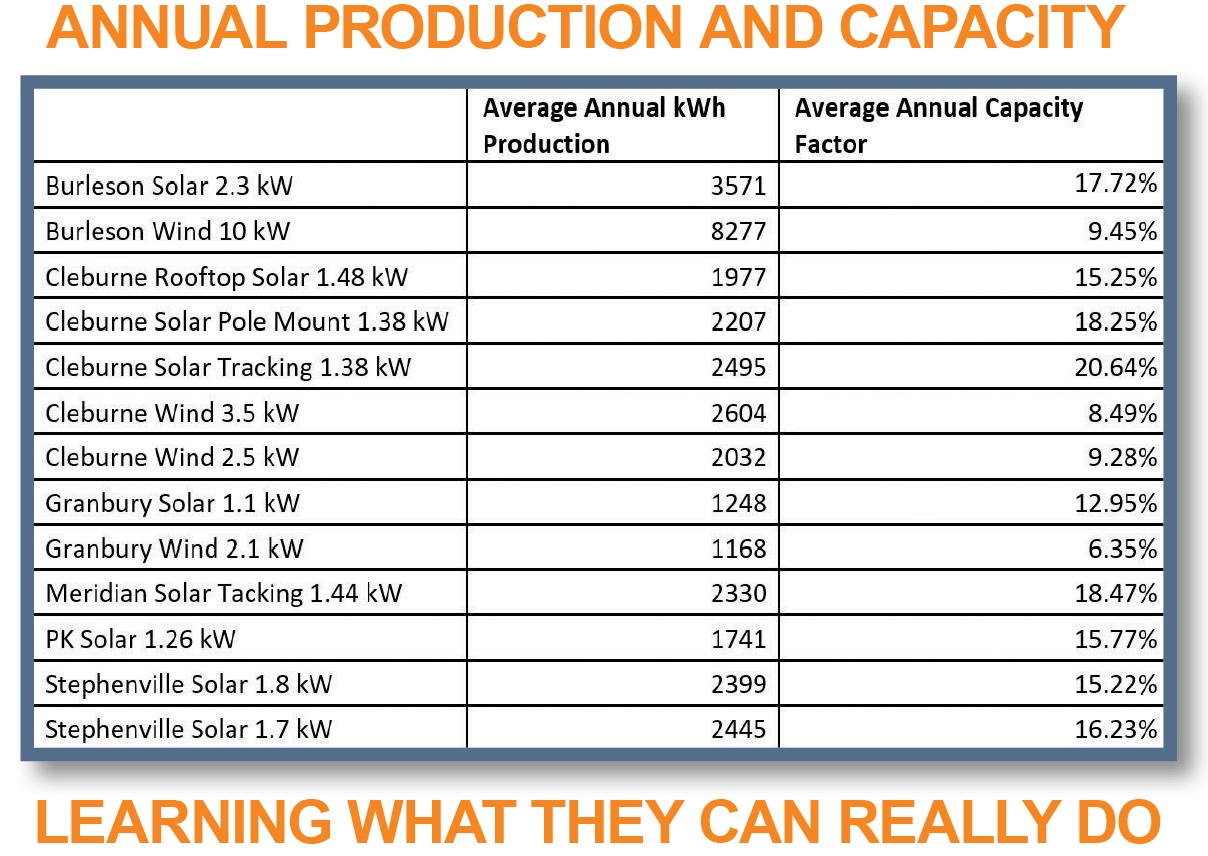

United records two different sets of data (kWh energy production and the capacity factor) every month for each of its renewable energy lab applications.

Capacity factor is the actual energy production output over a given period, compared to the maximum possible energy output over that same period. For example, if a solar array produced at maximum capacity, 24 hours a day, over an entire year, its capacity factor would be 100 percent.

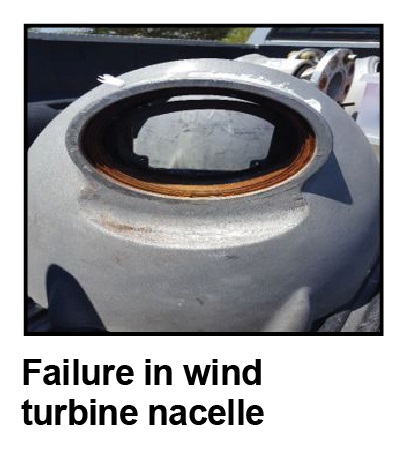

A chart on the following page shows the average annual kWh production and the average annual capacity factor for all 13 systems United has monitored for the past seven years. Based on these comparisons, solar arrays have a higher capacity factor when compared to the wind applications in our service territory. If a member were trying to decide whether to invest in a 5kW wind turbine, or a 5kW solar array in our service territory and both systems were priced equally, the member would want to install solar because more energy production would come annually from the solar application compared to the wind turbine.  Also, wind turbines are more maintenance-intensive than solar applications since they have more moving parts. The 2.1 kW Skystream wind turbine located at United’s Granbury office, for example, has seemed riddled with mechanical issues—even leading to a failure within the turbine’s nacelle that required lowering the entire tower and disassembling the turbine for repair (photo at left). In addition, United has recorded four instances of wind turbine blade failures at other office locations that included chipping, cracking and fracturing within the blades.

Also, wind turbines are more maintenance-intensive than solar applications since they have more moving parts. The 2.1 kW Skystream wind turbine located at United’s Granbury office, for example, has seemed riddled with mechanical issues—even leading to a failure within the turbine’s nacelle that required lowering the entire tower and disassembling the turbine for repair (photo at left). In addition, United has recorded four instances of wind turbine blade failures at other office locations that included chipping, cracking and fracturing within the blades.

Problems haven’t been limited solely to the cooperative’s wind turbines, however. United’s solar demonstration projects have demonstrated their fair share of maintenance issues. Problems have surfaced with failing inverters, blown fuses and even damaged racking materials.

Based on those lessons, it is worthwhile for members to have some sort of monitoring platform to track the production of their system. These software platforms typically alert system owners if problems arise within the system.

To that point, it is important to note United does not monitor total production of a member-owned solar array. The cooperative can only see the excess solar production recorded through its net meters, which are installed after the solar array is connected. Net meters have multiple registers that keep track of the bidirectional flow of energy. These registers record delivered energy, received energy, and net energy. When the member’s consumption of energy is greater than energy generated by the solar system, energy will flow from United’s grid to the member and appear on the delivered (DL) register. When solar generation is greater than the member’s consumption level, excess energy will flow from the member to United’s grid. This excess energy is tracked on the received register (RC).

Finally, a third net register calculates the difference between the delivered and received register. United bills these accounts on the net metering rate, or the difference between the delivered and received registers.

In short, the member’s PV array is tied directly to the house and feeds the home first. If the solar system produces more power than what the home consumes, then United can see the excess through the received register on the net meter. This does not mean United can see the total production, because some of that energy was used to power the home. Due to this fact, if a member’s solar array does have a malfunction, and the member doesn’t have a way to monitor their total production, it could be months before they might notice they have a system issue.

One thing worth remembering about an investment in renewable energy resources is consumers must be prepared to commit to some level of upkeep on renewable energy systems to ensure the optimal operation of their equipment and investment.

As these types of renewable energy resources improve, or more renewable resources get introduced, United will continue to inform members about these new technologies, their pros and the cons and their economic viability from a consumer’s perspective.